Capacitive Touch Panels

The main components of a capacitive touch screen are the cover window, touch sensor, and touch control panel.

Cover window

The cover window (usually called "cover glass") is mechanical protection and a decorative element of the entire module. In most cases, the manufacturers use glass to make the cover window The typical protective glass thickness is: 0.55, 0.7, 1.1, 1.8 mm.

The standard thickness of the cover window in the LUPHITOUCH module is 0.7 mm for the 2.8-5.0 inch size and 1.1 mm for the 7.0 inch size.

For glass, a common phenomenon is the subtle green hue of the material. It is particularly noticeable at the edge of the screen. The reason is that it contains iron oxide. In some cases, it is necessary to use ultra-transparent glass to eliminate this effect (to maintain the original color).

Another thing is the safety of the glass. To achieve the safety of the glass manufacturers tend to rely on the post-production process of strengthening the glass. The most popular properties are chemical strengthening (maximum 3mm) and thermal tempering (performed for glass over 3mm). Heat-treated glass is safe in comparison to non-heat treated glass mainly because heat-treated glass would break into small, non-sharp particles (and therefore dangerous).

The last step to ensure the safety of the glass is to make a C-cut on the edge of the cover glass. This treatment can protect the edges from cuts and dents.

As mentioned in the previous paragraph, alternatives to glass are synthetic materials, such as PMMA or polycarbonate. The choice of covering material is suitable for working conditions and the environment.

Touch sensor of Touch Control Panel

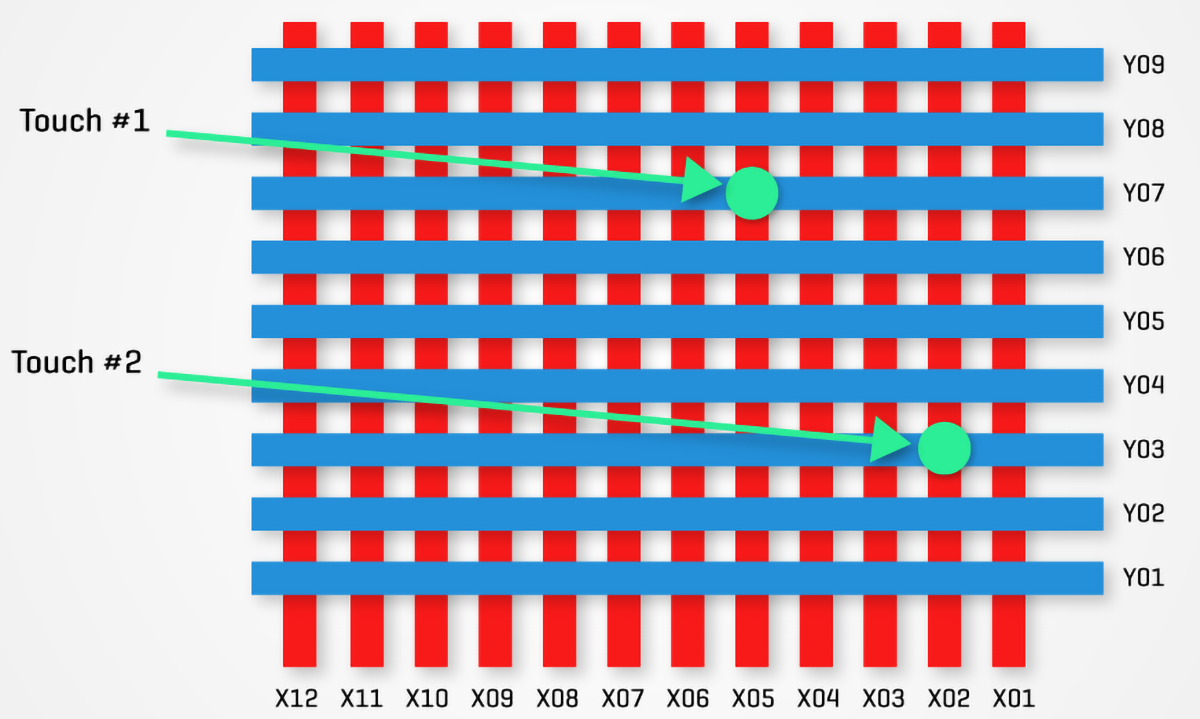

Regardless of the material you use for the cover window, the basic structure of the sensor uses two insulating layers, ITO (Indium Tin Oxide). It is important to arrange the layers in rows and columns placed vertically to create a matrix.

In order to achieve the function, it is important to scanning along each axis and identifying high-capacitance lines. Then, the machine determines the position by the intersection of these lines (with high capacitance):

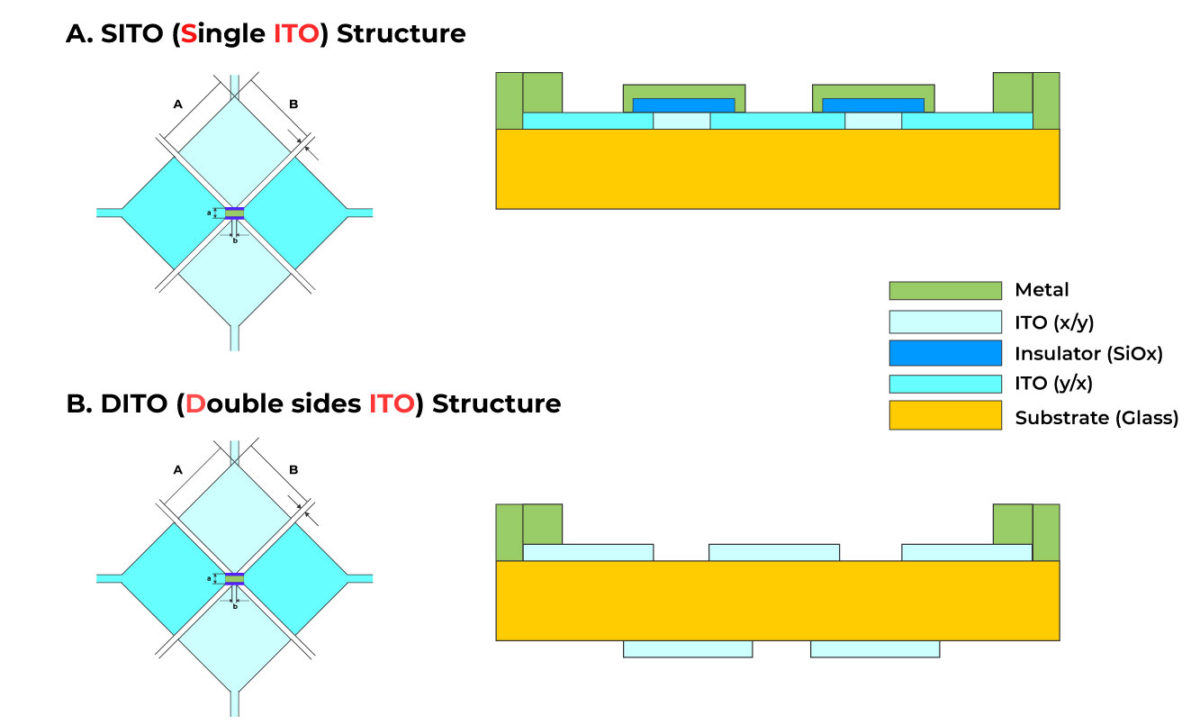

Manufacturers use the Double-sided ITO glass in order to make the touch sensor. The pattern of the sensor is created during the etching process.

It is worth mentioning that there is a technology to obtain a touch sensor with a single layer of ITO glass (SITO). As shown in the figure below, this can be done by etching the sensor pattern on one side and then bonding specific X or Y electrodes.

CTP control board

The sensor ends with electrodes-electrode data that you need to collect and manage from the controller.

The choice of the controller should be in accord with the application of the module and the environment that you plan to use. Therefore, itis important to consider a number of factors. The first step is communication-you need to set up the touch screen interface. The most popular interfaces are SPI and I2C. The LUPHITOUCH touch controller also communicates via SPI/I2C.

Next, the size and the efficiency and safety of the control board should be considered. In this case, electromagnetic compatibility (and therefore electrostatic discharge and radiation sensitivity) should be analyzed.

The IC can perform various functions that should meet the requirements of the application. You can find ICs suitable for water performance or salt water environments, as well as ICs that support gloves and special gestures.

The LUPHITOUCH offers outstanding quality Touch Control Panel. Our standard controller supports coverslips up to 2 mm. Although we are familiar with the technology that supports protective glass up to 5 mm thick.