Choose the Best Technique That Correctly Labels Membrane Switches

Comparison between Membrane Switch Printing Technologies

History shows that printing goes way back in time. There are many instances that show the occurrence of printing technology even in earlier eras. The art of duplicating refers to stamping.

Even the earliest of civilizations that date back to 3000 BC shows artifacts that are related to printing. They used circular seals for making impressions in clay for maintaining and keeping up information.

These seals also referred to as labels, were very common in surviving the earlier days.

However as time passed, people started incorporating technology for their labeling and stamping needs. They invented printing press tools for making labels in larger quantities for bookkeeping, magazines, and including more reading materials.

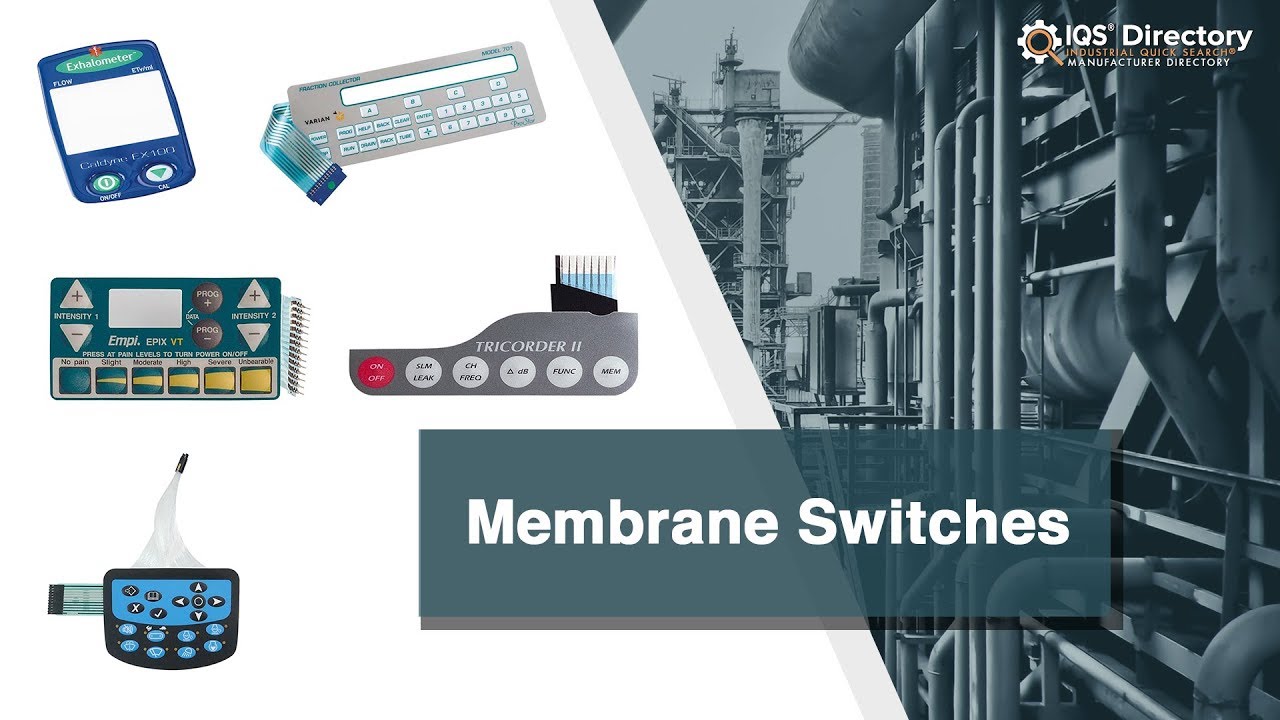

Technique That Correctly Labels Membrane Switches

The use of labels comes in very handy when keeping lodges in larger quantities. Hence, mass-produced books, magazines, and newspapers required proper labels for easier approach and sorting.

Technology is spreading its way in our lives in unique and more important ways. In fact, it is only possible with the use of label switch printing skills, that we are able to incorporate membrane switch Technology in our lives today.

The use of membrane switch technology has become a resourceful way for making direct solutions that involve concerns regarding the environment.

Membranes switch technology requires very little keep up hence it is great for mass production. The designers are taking great initiative in taking steps for designing label switching technology for various printing needs.

A number of different designs and printing technologies include Digital Printing screen printing lithographic printing and flexographic printing.

Digital Printing and Labeling Membrane Switches

Digital Printing does not require any underlying substance or layering. In fact, it doesn't even require any special kind of ink to perform printing.

The process is quite simple. In this technique, information about instructions passes out from a device. This device can be anything that can pass on information. It can include computers and portable devices.

Usually, the process takes very less time once the instructions pass on. The printer attached with the computer on the portable device carries out the instructions in the form of a printed file. The most common form of information sent is as a PDF file. This format is easily readable by the printer, thus the results are immediate.

Digital Printing

When compared, digital printing is way better than screen printing. This major difference is due to its lower production cost. Another major factor that makes digital printing stand out is its remarkable impact on the market. It is an efficient and organized procedure that goes without a hitch. It streamlines the process for easier manufacturing. Furthermore, digital printing totally basis on demand so there is no wastage of resources.

Ideally, digital printing is most suitable for membrane switch designing. It fully suits the users’ requirement for making effects like fades, texturizing, and consistencies that need compliance when dealing with 3-D graphics.

It is becoming a technology that is extending its branches very fast. The technology of digital printing is urging researchers to develop new tools that facilitate more features. Its new approaches are helping in more compatible designs that are user-friendly.

The main users of this technology are solely responsible for enhancing its futuristic techniques and rising demands. Laser printing is a part of digital printing that is becoming way more popular for better results like clear and quality production of texts and graphics. Its stunning results are aiding the industries in opting for printing tools that produce high-quality results.

Screen Printing and Labeling Membrane Switches

Screen printing is one of the oldest techniques that date back to 960AD. It has its origin related to China. When compared to digital printing screen printing is way more complex. It makes use of an interlaced net. This supports the anti-spoiling of ink stencils.

It easy to use screen printing for monochrome images, but for multi-color images, it can get complex. Thus, it is important to use numerous screens when making use of more than one color.

The use of screen printing helps in printing the circuit nonstop. This is especially feasible on plastic substrates while producing membrane switches. The printing process comprises silver and carbon ink that is a conductor itself.

Screen printing can easily compete in the race for labeling membrane switches. It has a high success probability. Although, digital printing is taking over the conventional method of screen printing it still caters to its own niche.

DrawBacks

However, there are some drawbacks that can link to screen printing. They include limitations when production is needed in large quantities. It can majorly hinder the cost-effectiveness by soaring them unreasonably. This certainly drives manufacturers of labeling membrane switches away.

It is important to know here that screen printing is still a common practice for some manufacturers. Sometimes, users integrate both digital and screen printing techniques to gain their desired level of printing needs. A common example includes the use of screen printing for circuit layering and digital printing for making graphic overlay of the design.

Lithographic Printing and Labeling Membrane Switches

Lithographic printing is a technology that relies on integrating two different saturating features for producing the image needed. It involves the use of photographic procedures like making negatives.

A lithographic plate is the part of lithographic printing. It can either be of plastic or aluminum that is flexible in nature. The plates related to this kind of printing are modern in type and have a rough texture. It has a photo-sensitive coating that features photographic negatives.

This plate then confronts light for results. After developing the coating, it helps in showing images of the negatives produced. Consequently, it is duplicating the earlier image. This plate reacts chemically to produce images that are responsive to the conductive ink. It is not very a common choice when developing membrane switch labeling.

Flexographic Printing and Labeling Membrane Switches

Flexographic printing is a technology that revolves around the rotation release method for printing. Its printing plates are made up of plastic, rubber, or other elastic materials that support printing.

Lately, using polymers in printing techniques shows that there is a significant rise in the life and resolution quality of the images. By using the elastic stamps the image takes its place on the plate. With the help of rotation, they place the ink by leaving its mark.

They use the engraving technique which refers to an anilox. Anilox is a roller that has small compartments throughout its surface which help in transferring the amount of ink required during the printing. This wipes off the extra ink effectively by keeping in check with the rolling rotators.

It provides efficiency by controlling the ink transfer made during the process. It is a feasible method for developing membrane switching labels effectively.

![]()

Summary

It is always important to make an intelligent choice when choosing the right method for printing labels for membrane switching. Either it is digital printing; screen printing, flexographic printing, or lithographic printing the label should serve the purpose of creating the membrane label in a fast and effective way. It is important to keep the functional requirements in mind when designing the membranes by consulting with the membrane designing team.

For More Information, Contact Us Today!