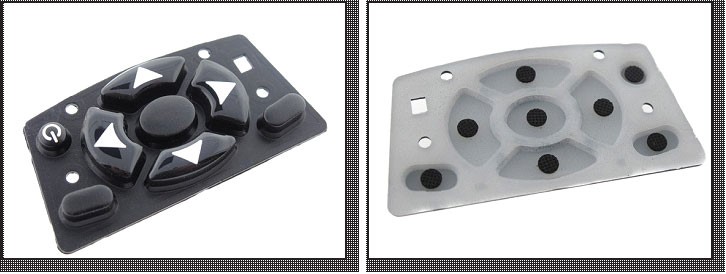

Comparison between Conductive and Non-Conductive Rubber Keypad

Comparison between Conductive and Non-Conductive Rubber Keypad based on their Construction

What is Rubber Keypad?

The term keypad may refer to a furnished bezel, a moulded silicon and sometimes referred to the entire keypad assembly that constitutes a printed circuit board. It is essential to note that instead of being a self-employed part, a rubber keypad is a part of the keypad assembly. It an electrical switch made of excellent webbing rubber which holds compression moulding properties.

This top-of-the-line interface widely used in consumers and industrial electronic products. It combines the haptic feel and optimal functionality because it is durable, customer-specific, cost-effective, reliable and exceptionally resistant to UV rays, extreme weather, chemicals, moisture, abrasion, and ageing.

Keypads are sometimes made with high-pressure rubber moulding technique, but typically low-pressure density moulding procedures are applied in their make. Majority of them retard flames. They can either be transparent or integrate solid colours and they may combine transparency and solid colours.

They can even have varying solid colours within separated areas. The laser-etched keypads support backlighting option to add an aesthetic touch to the product. An inactive layer exists within the keypad to avoid the switches from executing until pressure links to the printed circuit board.

The keypad has visible rubber keycaps or buttons integrated into a base mat that leans against a printed circuit board, which gives the keypad the capability to perform. The three-dimensional keycaps are usually glazed with a wear-resistant crust and serve different purposes.

Legends on keycaps are laser engraved or transparent rubber coated with silicon paint or embossed with selected silicon liquid ink. The user senses a physical click when pressing the buttons when the pressure on buttons is released, and they get back to their normal state, giving a positive response.

Choosing Suitable Rubber

Choosing the most suitable rubber keypad becomes a difficult job because it comes in two classes. Both the keypads are manufactured from different perspectives. The construction of both varies from a technical point of view. For a better understanding, the structure of both is briefly given below.

-

Structure of Conductive Rubber Keypads

These keypads directly link with the printed circuit board, and the action takes place on pressing the keycaps. They contain a puck on their rear surface or a semi-conductive pill permanently attached to the lower of the keycap bottom at each switch position in the finishing moulding process.

You should position the pills in the mould alike as in case of electrical connectors. They compose a balanced mix of silicon rubber and carbon particles. The latter’s presence makes the keypad’s surface conductive, and the silicon rubber keeps the carbon particles together.

The semi-conductive pill physically connects with visible conductors on the printed circuit board with its surface parallel to the circuitry on pressing the keycap. As a result, there is a formation of an electrical switch closure after keycap travel.

Due to ease in its construction and intuition of tactile feel, the rubber keypad is reasonably standard among a large number of industries and individual users.

-

Structure of Non-Conductive Rubber Keypads

They look like conductive rubber keypads but are more imperative since they act as controller against the switch mechanism. They bend and conduct the circuit after getting in touch with the flexible sheet above the circuit. Lack a semi-conductive pill or puck on the keycap's rear and instead, integrate a metal snap dome switch to provide a naturally distinctive feel.

Manufacturers place a thicker web of material between the keycap and the base that does not allow it to flex much. The lack of force cone restraint improves keycap’s movement, and it becomes relatively less disposed to tear or crack. Unlike conductive rubber keypad, non-conductive keypad uses higher durometer of silicon rubber to produce the preferred results.

Comparing Features of the Two Rubber Keypads

The users can compare two keypads' following features before finalizing the best option that suits their work.

-

Operative Force

To deliver a tactile touch and support long travel, the conductive rubber keypad hinges on upon an accentuating force cone that lies at the edge of the keycap. The usual range of this operating force is 60 to 200 grams.

In non-conductive rubber keypads, the active working force is the amount of one-dimensional displacement force of non-conductive keypad and the metal snap dome switch's dynamic power. As a result, the operational capacity is passive in non-conductive rubber keypads. The normal range of this force is 240 grams to 2000 grams varying according to the dome switch's design.

-

Keycap Wobbling

We can see that the conductive keypad behaves well when we press the keycaps from the centre; otherwise, they tend to wobble. It happens due to the use of forcing cone, and the user misjudges the switch being closed electrically.

In non-conductive rubber keypads, due to lack of moving cone for a tactile impulse, the off-centre press is negligible. Since they use high durometer rubber, the keycap nod and switch closure opacity are eradicated for the user even if he presses the keycap off-centre.

-

Keycap Travel:

As keycaps produce a tactile sense by travelling a little longer in conductive keypads, the user feels haptic about the function's performance.

An average keycap travel in conductive rubber keypads ranges from .03 to .07 inches. The keycaps in non-conductive keypads travel up to .022 inches or even less depending on the outline of rubber actuator, the diameter of dome switch, and its operate force. In non-conductive rubber keypad, the tactile impulse is superior due to the short travel of the keycaps

-

Switch Bounce

When we press a conductive rubber keypad, we feel a more significant switch bounce. It happens due to amplified closed resistance created by the force of finger and the even thrust of the pills against the printed circuit board. In non-conductive rubber keypads, switch bounce truncates because the dome switches in such keypads possess low closed switch resistance.

-

Switch closing

In conductive keypads, the switch cavities – a place of two switch connections - cannot be closed because they need a free volume of air to execute the job when keycaps are pressed.

However, these cavities can project themselves to evade external contamination from passing into the keypad. In non-conductive rubber keypads, manufacturers seal the cavities besides minimizing the external taints affecting the keypad.

-

Intermittent Switch Operation

Since it is impossible to seal the switch in non-conductive rubber keypad, the switch cavity tends to catch dust. As a result, it displays irregular switch operations, and the performance of the button weakens afterwards.

In non-conductive rubber keypads, the metal impulsive dome switches function in a sealed cavity. The keypad is safe from external contamination and produces a higher tactile feel.

-

Switch Operating Point and Over-Travel

In conductive rubber keypad, electrical contacts only occur when pills make physical contact with the printed circuit board at the end of travel.

Typically, the switch operative point is near 90% of the keycap travel comprising over-travel in the conductive rubber keypad. In non-conductive rubber keypads, the electrical contact occurs on collapsing of the snap dome switch. The switch operative point is near 60% of the keycap travel comprising over-travel in the non-conductive keypad.

Take-out

Manufacturers use moulded silicon rubber for development of rubber keypads. The high-quality rubber keypads involve modern techniques in their make. They come in two different styles. However, when should always look for those that can best suit our needs.

\Accordingly, learning about working features, optimization and limitations of the user interface like the rubber keypad help us recognize the merits and demerits of its construction. We are in better shape to choose which keypad serves our purpose the best.

For More Information Contact Us Today!