Incredibly Tips for Membrane Switch Design Technology

What is a Membrane Switch?

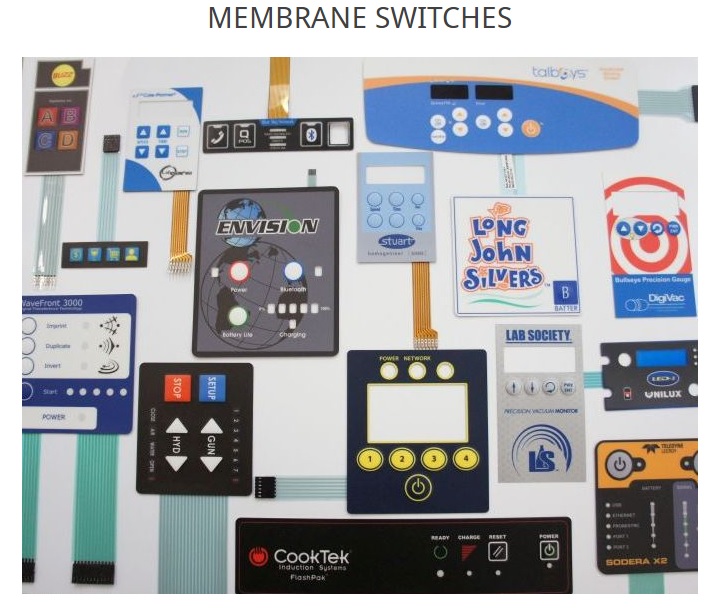

Electrical switches have long been the standard in various applications used across a wide range of industries to activate and deactivate circuits. A membrane switch is a multi-layered, plane electrical switch designed as an interface to address an explicit set of criteria depending on the use of the application.

Since its inception in the early 70s, this switch has gradually replaced traditional mechanical switches to become an indispensable component of sophisticated electronic and life-saving medical devices.

It is highly revered for its compact design, high conductivity, integration with other control systems, flexibility to operate in mild and harsh environments, durability and reliability in addition to ease of cleaning. A typical switch reinforces any application from unyielding PCB design to ultra-elastic membrane board with surface mounted LEDs.

How does a Membrane Based Switch Work?

Due to its simple design, the actuator only presses the switch. The system’s two ends make contact and close the circuit. On release, the ends cut off, and the control gets back to its open state. What distinguishes it from traditional switches is that it uses conductive ink, allowing for a smooth connection.

Types of Membrane Based Switch

You use two types of switches to execute different tasks on the circuit board.

Tactile

In usual practice, their design incorporates metal domes, and they actuate when pressed by an actuator. On pressing, the dome thrusts against a conductive print, and the action takes place.

Non-tactile

A non-tactile switch is an independent unit with the bottom of the overlay connected to a conductive pad. It functions similarly as a tactile switch but does not give tactile feedback.

Design of a Membrane Based Switch

Unlike a mechanical switch usually constructed with plastic and copper, a membrane push switch uses a conductive stainless steel dome connected to a circuit. The circuit characterizes the use of conductive graphite, carbon or silver ink printed on a high-quality indium tin oxide or polyethylene terephthalate film deposited on a flexible polyester substrate.

The switch also embeds low profile electronics within its laminated layers, such as optical fiber, light-emitting diodes (LED), an electroluminescent (EL) for backlighting.

The amalgamation of the low-profile dome and plane printed circuit makes it possible to fit the switch in applications where little space is available.

Due to its carefully crafted design and a high degree of visibility, a membrane switch is used in many high-end applications. It is used in consumer products, life-saving devices, defense and aerospace technology, industrial and transport controllers, keypads of hand-held gadgets, etc.

Guidelines to Understand the Membrane Switch Design

A classic membrane push design involves four layers, the top one highlighting the graphic interface between the actual apparatus and the user. The design of a reliable, durable, and eco-friendly interface takes care of environmental factors, electrical and mechanical requirements, appearance, and compliance to safety standards.

Ultraviolet Hard Coating

The membrane push switch can withstand harsh weather and UV rays of the sun with ultraviolet coating, especially when exposed to the outdoor environment. The ultraviolet hard-coat enhances its appearance, performance, and, most importantly, durability.

Overlay Material

The membrane-based switch uses either polycarbonate or polyester as a substrate for the graphic overlay. The concrete transparent substrates become solid and non-transparent when graphics are produced on the overlay's reverse side.

Type of Circuit

The switch may contain any of the three types of circuits: a) Rigid Circuit, b) Printed Circuit c) Flexible Printed Circuit

Graphics and Artwork

As the switch's uppermost layer, the graphic overlay serves as a direct interface between the user and the product. Graphic overlay improves the visibility of logos and other functional indicators from varying angles at a distance.

The artwork variations also enhance aesthetic and functional differentiation. Careful applications of texture coatings increase durability besides keeping high visibility of lower layer displays.

Embossing

Pad, dome, and rim are embossing forms that give a three-dimensional look to the switch panel. Although polycarbonate substrate is suitable for crisp embossing, it is usually not the first choice for switches due to its limited flexing character.

Polyester is a better choice for embossing due to its excellent flexibility. In order to emboss polyester overlays, you can use heat stamping.

Color Matching

The design should use a CMYK color model to complement custom colors.

Moisture Resistant

The interface design must ensure that it is environmentally impenetrable to avoid dirt, liquid spills, chemical ingress, and humidity impact. Acrylic adhesive applied to both sides of the spacer layer can effectively perform environmental sealing. Carbon should be coated on any exposed contacts to save them from damage due to condensation.

Electrostatic Discharge/ Radio Frequency Interference Shielding

Design the switch so that it carefully protects the interface from electrostatic discharge when a human contact the switch. The transfer of highly potential electrical charge may damage the components of the apparatus.

An ESD shielding using aluminum foil or printing a carbon silver grid can safeguard the ESD impact switch. The high-frequency radio waves may also impact the operation of the user interface. It, too, requires RFI shielding to the switch to keep it safe from interference. For effectiveness, it should border the entire switch.

Tooling

The design should involve steel rule die tooling or hard tooling to make a custom membrane switch. It gives tolerance to the switch to bear thousands of strikes before replacement.

Venting

The environmentally sealed switch should have internal and external venting. Also, these applications' design equalizes pressure within the switch cavity with the surrounding atmosphere, causing the switch to close appropriately.

Since external venting can create contamination risk, it should be done only where the switch is exposed to significant atmospheric pressure variation and less exposed to the harsh environment.

Tactile Feedback

It evades chances of errors by involving stainless steel metal dome constructions for high reliability and higher actuation. As an integral part of most circuits, the dome produces tactile feedback and closes the circuit when pressed. You keep in mind the size, shape, and actuation force when designing the dome.

Backlighting

Backlighting provides the user with clear visibility of the keys, signs, and logos on the switch. So, some of the backlighting options are light-emitting diodes (LEDs). They work best for status indicators, an Electroluminescent (EL) lamp most appropriate option in low light situations, and an optical fiber that lasts for 100,000 hours. All these options are inexpensive and energy-efficient.

Windows

The design should employ clear windows in the switch depending on the type of display. LCD, for instance, needs clear windows. LED display, however, need even less clarity.

Adhesive Selection

These are the substances manufacturers use to bind the surfaces of different layers of the switch and avoid separation. They should be excellent resistant to solvents, chemicals, and heat.

Connectors

We recommend two types of connectors for a typical switch. a) single row/crimp connector for gas-tight termination, and b) ZIF (Zero Insertion Force) connector that needs minimal force for insertion.

RoHS Compliance

The design should ensure that the switch does not incorporate banned components. The polyester film used for the substrate, the inks used for graphics, and pressure-sensitive adhesives are usually authentic substances free from any restriction.

Summary

Membrane switch offers distinct benefits for a variety of applications. A completely impenetrable design provides a complete solution for any harsh surroundings with a low risk of failure due to moving parts' cracking.

Its low cost and reliable performance make it a perfect switch when the question arises about dependable user-interface solutions. Excellent design expertise and compliance to RoHS make a membrane-based switch an ultimate choice as a user interface for many electronics. The set of design guidelines is to help you choose the ‘this is it’ type of electrical switch.