OCA Lamination Membrane Keypad -- Introduction to OCA Lamination Machine

Role of OCA Lamination Machine in the Manufacture of OCA Lamination Membrane Keypad

An OCA lamination machine plays a vital role in the assembly of the OCA lamination membrane keypad. The process utilizes an optically clear adhesive or OCA which binds the various foils of the membrane keypad together.

You can find OCA lamination membrane keypad in a wide array of applications that range vastly in terms of complexity. The prevalence of these keyboards is due to their durability, aesthetic flexibility, cost-efficacy. And most of all, ease of production courtesy of machines like the vacuum lamination machine.

Sensing the importance these machines have in the assembly of membrane keypads, we thought the OCA lamination machines deserve a focused introduction. Therefore, in this article, you’ll find a concise but comprehensive introduction to lamination machines.

But, before we begin discussing the lamination machine, we must talk about the membrane keyboard. So that we can get a better understanding of the machine.

OCA Lamination Membrane Keypad

OCA lamination membrane keypad gets its name from OCA lamination, which binds the different foils in the membrane keyboard assembly.

The OCA lamination membrane keypad is an intuitive human to machine interface (HMI). Also known as a membrane switch, this keyboard acts as a communication bridge between humans and machines. It relays human information to the computers working at the backend of the machines.

These membrane keypads find numerous applications in a vast variety of machines. And can perform task ranging from as simple as switching the light on stage. To as complicated as translating some information to the computer.

Assembling of Membrane Keypad.

The OCA lamination membrane keypad is made after assembling different layers of foils.

The process begins with the production of a conductor foil. After which, a laser perforator creates holes in the adhesive and spacer foils according to the conductor foil’s assembly.

Once all the foils are ready, its time for their assembling.

It is the assembling of the membrane keypad where the lamination machine comes in. The operators arrange all the foils of the membrane keypad on top of each other and send it into the lamination machine, which binds the foil together through a process that we will discuss below.

The lamination machine binds the foils through different lamination methods. These methods include a liquid optical clear adhesive (LOCA), optical clear adhesive (OCA), and air gap bonding method.

However, since we are talking about OCA membrane keypads, so we will limit our discussion to the OCA lamination method.

Lamination Machine: Introduction

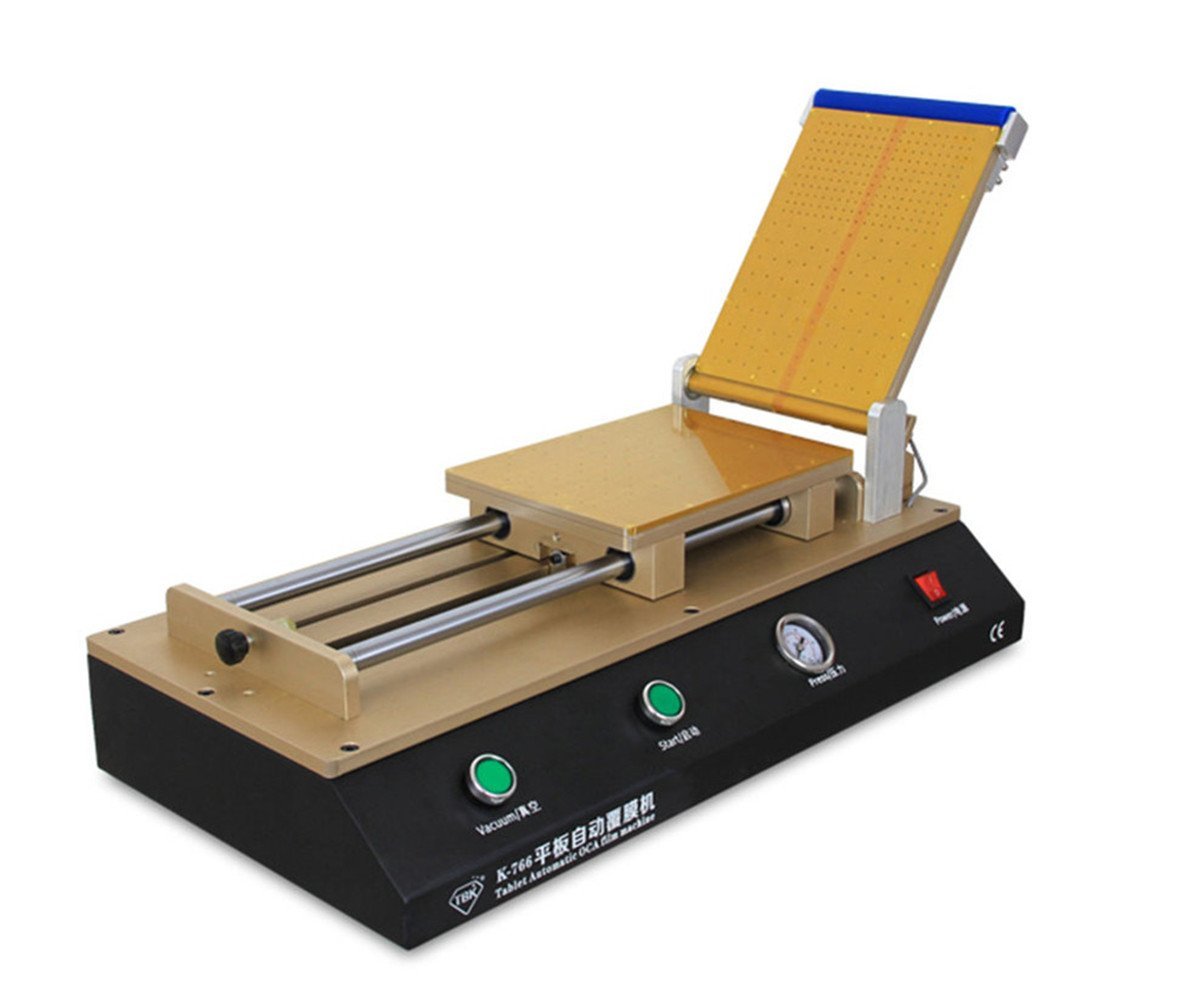

OCA lamination machine uses vacuum pressure and heat to stick clear, thin and sensitive layers together. it carries a heating unit and a vacuum assembly. The heating unit heats the OCA adhesive and the vacuum assembly generate negative pressure to ensure that the layers seamlessly adhere to one another.

The OCA lamination machine is mostly popular for repairing mobile phones with cracked LEDs as it handles thin, sensitive LED screens with diligence.

However, the membrane keypad assembly process also makes use of the lamination machine’s feature, which we will discuss in a bit, and produces top-notch quality keypads with no air bubbles or dust trapped between the layers.

Working of the Lamination Machine for Membrane Keyboard Assembly

The OCA lamination machine works on the principle of the OCA bonding process.

The lamination machine employs a vacuum system with a vacuum pump and a heating element. It also consists of a PLC which controls the operating parameters of the process and optimizes it to ensure proper lamination in each run.

After the operators place all the foils of the membrane keyboard on top of each other, they place it inside the vacuum box of the lamination machine. The vacuum box subjects the membrane keyboard to negative pressure and heat. The heat melts the OCA glue and negative pressure binds the foils seamlessly.

The OCA bonding process in the lamination machine is entirely automatic, with PLC controlling the process. The human operators only need to place the keypad foils, operate the machine and remove the keypads once they are assembled.

OCA Lamination Machine- Benefits

The OCA lamination machines offer a host of benefits over manual lamination which include:

Heat Regulation

The biggest problem that operators encounter during OCA lamination is that it needs an optimum amount of heat to melt the OCA glue. However, too much heat runs the risk of damaging the heat-sensitive conductive components of the OCA lamination membrane keyboard. While too little heat will not melt the OCA properly, leading to inadequate lamination.

However, the automatic OCA lamination machine eliminates the issue of inadequate melting of OCA by regulating the heat during the lamination process. So that each lamination is seamless, adequate and of high-quality.

Bubble-Free Lamination

Bubble entrapment is one of the major issues associated with manual lamination. However, an automatic OCA lamination machine mitigates this issue by using high-pressure vacuum pumps. These vacuum pumps create a uniform negative pressure across the keypad frame.

The uniform vacuum pressure minimizes the risk of air bubble entrapment and leads to a seamless finish of the keypad.

No Entrapped Dust Particles

Another issue associated with the manual assembling of membrane keypads is that it may lead to dust entrapment between the foils of the keypad.

But since the lamination machine carries the OCA lamination process out in a vacuum box, therefore it also eliminates the risk of dust particles contaminating the products of the OCA lamination process.

Quick Turnaround

The manual lamination process is extremely tedious and time-consuming. However, since the OCA lamination machine is highly automated, it offers a shorter turnaround time as compared to manual assembling.

Moreover, because of its short assembly time, it can assemble a greater number of keypads in a given time frame. Thereby contributing to an enhanced profit.

OCA Lamination Machine: Features

The benefits of the OCA lamination machine that we have discussed in the previous section are courtesy of the features of the lamination machine that we will discuss in this section. These features include:

Ease of Use

The control panel of the OCA lamination machine is extremely intuitive and easy to use. Even inexperienced operators can pick up the basics of the operation of a lamination machine and can start manning it in no time.

The OCA lamination machine uses user-friendly touch screens and membrane keypads with simple commands that all the users can easily understand and use to relay the information to the backend computer or controller responsible for controlling the machine.

Multiple Laminators

We discussed how OCA lamination machines offer a quick turnaround time. With multiple laminators, the turnaround time of the automatic lamination process is multiplied.

Some OCA lamination machines come with multiple laminators. Therefore, they can assemble multiple OCA lamination membrane keypads in one go.

Cost Efficacy

Contrary to what may seem, the OCA lamination machine is highly cost-effective.

Because it features a quick turnaround time and higher profits, therefore, it promises a quick return on investment.

If you invest in a simple lamination machine, you’ll see that it is much more affordable than the ones that offer enhanced features since the price climbs up as the number of features increase.

Take Away On OCA Lamination Membrane Keypad

The OCA lamination keypad is a product of the OCA lamination machine that we have introduced in this article.

The OCA lamination machine comes with a vacuum system and a heating element and works on the OCA bonding process.

Because the lamination machine is highly automated, it features ease of use, cost-efficacy and may have multiple laminators. Moreover, it offers many benefits when compared with a manual lamination machine including no dust or bubble entrapment and quick turnaround time.

For More Information, Contact Us Today!