Printed Electronics: The Defining Trends

Printed Electronics and the Trends that Define Them

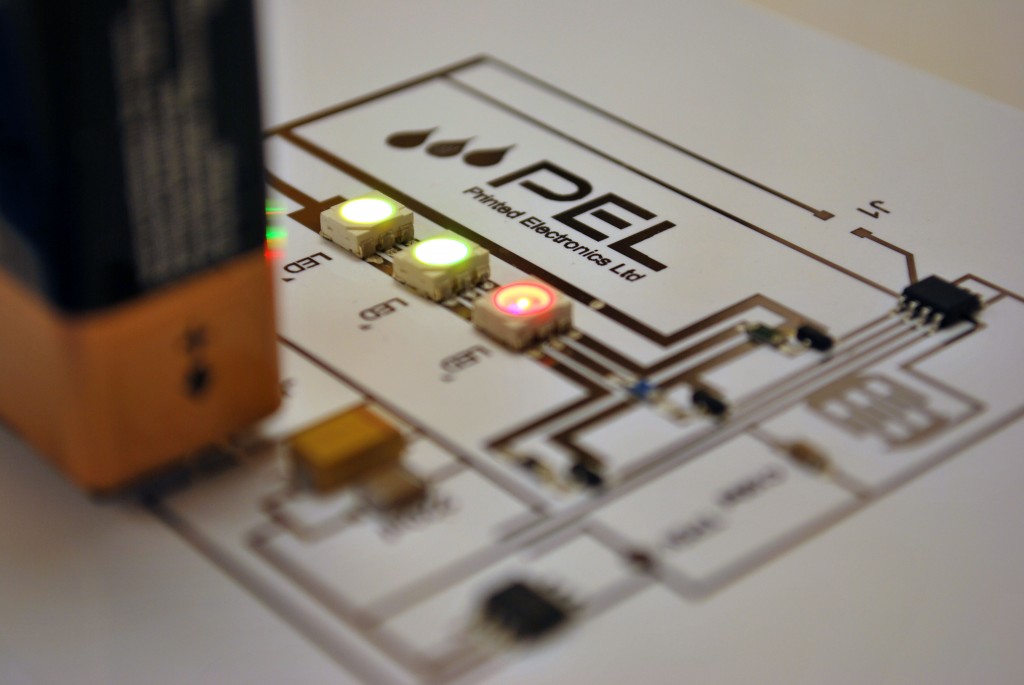

The printed electronics industry has recently made huge leaps in terms of mass production. Micro and Nano printing are futuristic ways to make products much more versatile. Electronics and their assembly are only complete when they pass all production stages.

Electronics that have a printed surface on top will not work the same way as the older versions. The increase in technological independence has removed all manual labor from the printing process.

The printing equipment is the biggest investment made in the classical process, this equipment has evolved. Every machine will give a different and specialized result according to the product you wish to print.

Furthermore, the human eye cannot detect most of the printed surfaces. Usually, the printed area can only seem larger when seen under a microscope or a magnifying class. Printed boards end up in electronics that we depend on today. Without this timeless advent in our midst, we would have been incapable of accuracy within production.

Understanding the Methods of Making Printed Electronics

Many paths lead to the crafting of printed electronics however the inkjet printing remains the most popular. An inkjet printer is a versatile machine that comes within an affordable range. For those who do not specialize in printing electronics, this is the ideal machine.

Although inkjet printers display lower throughput of around 100 m2/h and lower resolution (ca. 50 µm) they are still widely accepted as one of the best methods to create printed boars. The older printing process involved a multitude of steps, the concise order of these steps defined the process. The order of the steps matters because slight deviance can cause irreplaceable changes in the substrate.

You might understand the printing procedure of the paper. The printing of electronics has a higher degree of complexity than the paper orienting however at some places the terminology and workings are similar.

The printing procedure differs according to the method used for instance the inkjet printer uses direct deposition. The ink used in this printer is slightly thinner than screen printing. During the inkjet printing, the ink is deflected towards the substrate through a series of strong voltage. The voltage source acts as the backline worker during the whole process.

Furthermore, drop on demand inkjet is a category inside the inkjet printing procedure. Drop-on-demand inkjet does not rely on direct deposition and instead uses the voltage.

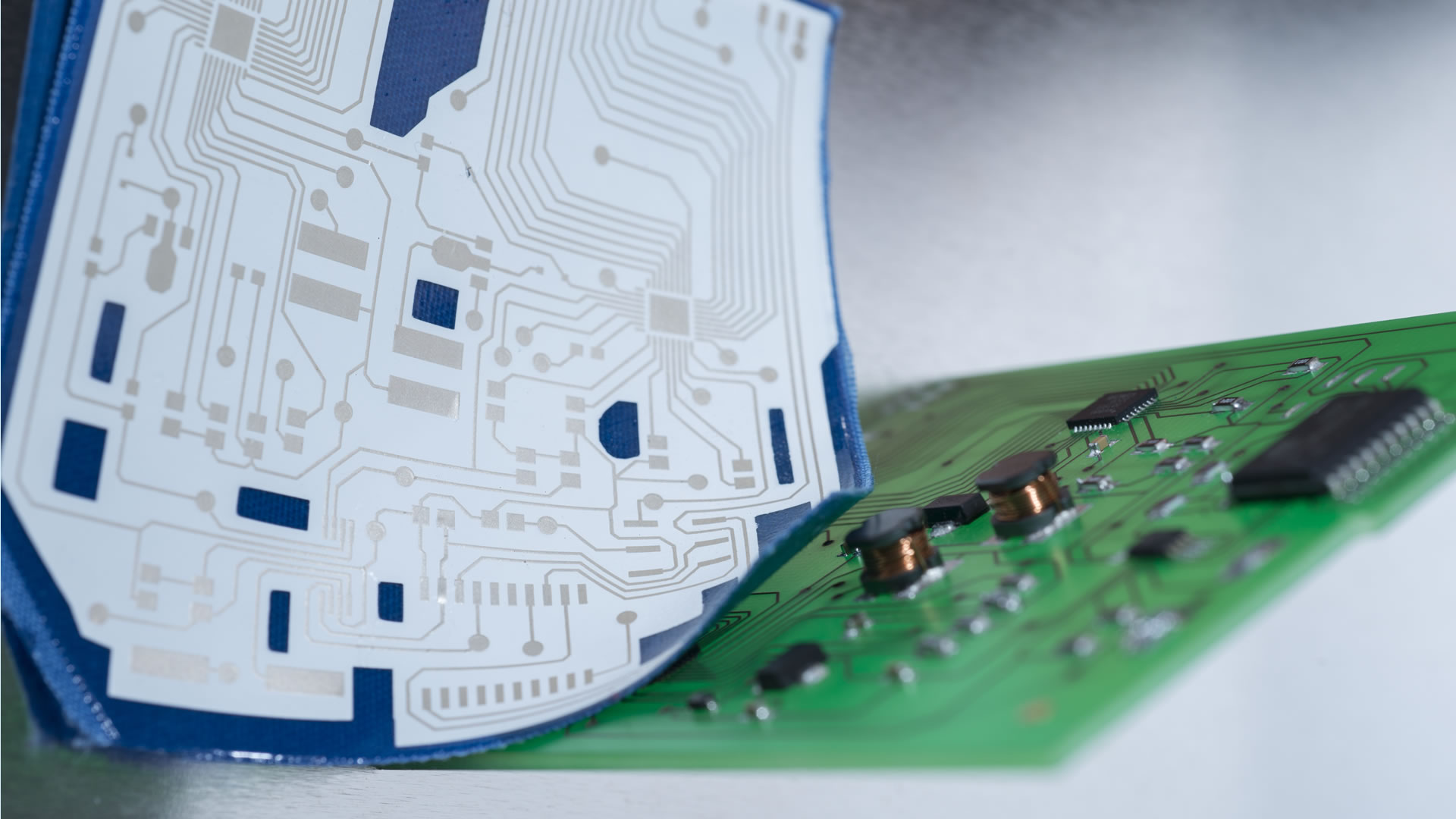

The ease in the fabrication process has led to the introduction of different substrates. You can employ substrates like plastic metal and even silicone while printed circuit board assembly.

Every substrate has a match with at least one procedure inside the printing family. The inkjet, gravure, flexographic, and screen printing techniques have made a huge impact in the electronics manufacturing industry, we cannot go back to the sullen production days now.

The Progress of Printed Electronics and Substrates in the Recent Years

The development of printed electronics from conventional methods was only possible with the time and attention of the industry heads. Even though the printed electronics industry is still considered emerging, the milestones achieved have made a mark.

The rapid increase in production methods occurred because the manufacturers performed printing every day. There is a lot of room present for improvement in this area and we are here to identify it. The choice of substrate is critical while performing printing since they can make or break the efforts of the printer.

The substrate releases surface energy that must coincide with the surface tension of the ink. Every printed electronic will follow a product life cycle which can only begin when the right tools are used for its production.

Polymer, paper, and glass were the most reliable choices for printing in many ways since the manufacturers did not want to experiment with anything bizarre. Recently, polymer substrates such as Polyethylene terephthalate (PET), polyamide (PI), and polycarbonate (PC) have begun to receive equal attention from the producers.

The polymer substrates ensure a lower cost moreover they appeal to those electronics that have a smaller function in a larger device, the quality of the polymer substrates remains constant no matter what printing approach applies to it.

Polyethylene terephthalate (PET) is the most common polymer substrate among printing professionals, it acts as a solid base for accurate printing. Apart from the substrates inks have an impact on the printed outcome as well.

Some printing methods like inkjet printing prefer viscous inks whereas others have a liking for a thick consistency. Ultimately, the choice for substrate boils down to the electronics’ future use. You can continue with the basic substrates without indulging in complex formulas since the added components are not necessary.

Defining the Latest Trends in Printed Manufacturing

The healthcare industry is directly tilting towards stretchable electronics; these electronics accompany the body everywhere. Healthcare is one of the most dynamic industries which appreciates the involvement of electronic parts.

Health is not restricted to the same acids and surgeries but has also included electronic management. Stretchable sensors are one such point of interest for companies that want to serve the medical centers. IDTechEx carried out their research while looking at all variables in the electronic future, the pass a trend profile on printed, flexible and organic electronics.

As far as printed electronics are concerned IDTechEx Research says that printed and flexible sensors hold a significant portion of the market share, more than OLED lighting and conductive ink in mold electronics.

According to the thumb rule, the market size will expand and so will the opportunities. The rends recorded might not have the exact same outcome but they are a reliable forecast for the impending future.

This marks the perfect time for investors to mark their territory in the rising field. Every new field such as printed electronics will bloom for a long time.

Furthermore, hybrid electronics are another rising trend for the future. Hybrid models were first found in small scale manufacturing and later most popularly discovered in cars however the hybrid modeling shall now occupy a larger space in the market.

The world is changing as we know it and the 5G launch in economically stable counties has increased the demand for conductive inks. In the coming years, 5G will become available in most countries like the already prevalent 2G and 4G. Those who manufacture conductive inks or invest in them can reap those benefits.

Take Away

The trends within the market define how much investors and manufactures should rely on a product. Printed circuit boards and electronics are currently ruling over the anno technology area.

Printing the substrates instead of manual exertion does not only remove the human error but also refines the area The benefits of using the printed mechanism sound more appealing when combining with the production cost.

The production for printing electronics is next to nothing given that the inexpensive machine creates hundreds of units. You will not find fault in a printed electronic since the substrate goes through intense quality checks.

These electronically active substrates eventually end up in the devices that we commonly use. The devices may range in application such as medical or industrial however the printed parts perform their function precisely.

For further information about the recent trends in printed electronics and their functions, take a look at our website now.