Printed Membrane Circuit The Science Behind Conductive Ink in Membrane Switches

Printed Membrane Circuit: The Science behind Conductive Ink in Membrane Switches

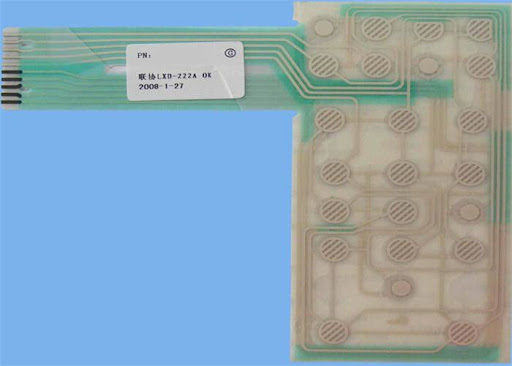

An electrical switch is available in several types. A membrane switch is one popular type of electrical switch among many others. The membrane switch is made using a flexible material. These switches turn on and/or turn off circuits. Conductive ink is a necessary element of the membrane switches to complete a printed membrane circuit.

Without it, a membrane switch cannot complete its operation. In this article, we will clear your concept about the role of conductive ink and how it helps the membrane switches operate.

Printed Membrane Circuits and Conductive Ink

To make the concept clear, we will try to discuss these things one by one. First, we will take a quick look at the membrane switches and their basics.

After that, we will discuss what conductive ink is and how it is used to complete a printed membrane circuit for final use. So, let’s start the discussion by discussing what membrane switches are and how they function.

Membrane Switches

A membrane switch is a flexible electric switch that offers functionality to a product. You can consider this switch like a product’s remote control. This is because these switches turn off and turn on the product and also help you perform other product functions. Low profile membrane switches need little design space when we compare them with other mechanical switches. Membrane switches are easier to maintain and cost-effective that makes them an easier and cheaper substitute to other mechanical switches.

Here are the different types of membrane switches that you should know before we move on to the science behind the conductive ink:

1. Tactile Membrane Switch

This membrane switch comes with the snap action, which is a user can notice clearly. The conductive domes remove the requirement of the top circuit layer to be flexible. The snap action dome can either be a gold-, silver-, or nickel-plated steel spring.

2. Non-Tactile Membrane Switch

This switch doesn’t provide tactile feedback like a tactile switch to users. However, there can be other feedback types, like display change, LED indicator, or sound beepers. This membrane switch type is an economical and reliable choice. One benefit of this type is that it helps design custom sizes and shapes.

3. Mixed Panel Membrane Switch

It is the combination of both tactile and non-tactile switches in one panel. This is suitable in situations where you need a big active part is required for a specific switch.

4. Rigid Membrane Switch

A rigid membrane switch can either be a tactile or non-tactile switch. The non-tactile version incorporates a silver printed contact with the space layer. They can be tactile if you incorporate a snap-action contact dome.

5. Flex Circuit Membrane Switch

This membrane switch type is an ideal choice for tough environments. It is a fixed copper lead-frame circuit covered in a polyimide or Kapton material. This switch has many benefits. You can also combine it with lower-cost alternatives of a tactile or non-tactile switch assembly.

A product can incorporate any of the above-discussed membrane switches. However, the selection of the switch depends on the specific requirements of the product. Therefore, different products come with different membrane switches.

Construction of a Membrane Switch

For a better understanding of the role of conductive ink in membrane switches, it is important to know about the construction of these switches. The construction of membrane switches varies from one switch to another. However, most switches have a few basic layers. First, there is a top layer featuring a printed design. After that, there is another space layer that follows the top layer. Finally, there is a printed layer that completes the design.

Below the top membrane switch layer, there is the electrical contact. The primary circuit layer also has electrical contact. These contacts meet after pressing the membrane switch with your finger to complete the circuit. Releasing the finger pushes away the top layer contact from the bottom layer contact which breaks the circuit.

Conductive Inks

Manufacturers infuse different conductive materials to make conductive ink. Such materials include graphite, copper, silver, and carbon. This infusion helps the ink electrically conduct within the product. Without conductive ink, it is not possible to make a printed membrane circuit. These circuits make your product functional, thus the conductive ink becomes a mandatory element of membrane switches.

Designers use this ink for producing BUS systems and traces for carrying and distributing power. This makes conductive ink a perfect option for membrane switch design. It is also used in many other interface designs that require flexibility.

How Conductive Inks Works In A Printed Membrane Circuit?

In a few simple words; conductive inks complete a printed membrane circuit. But, it is important to make sure that the conductive ink is ‘functional’. The ink that you use in the printed circuit creation and design needs to move the current.

Otherwise, we cannot consider the ink functional. Functional ink ensures printed circuit functionality. Two trace designs connect under the metal dome. These traces connect with the help of a metal dome after you press the membrane switch. As a result, it completes the circuit.

Then, the electricity starts to flow across the membrane switch, which provides off and on functionality. Once you take off the pressure by releasing he membrane switch button, the contact between the two traces is lost. Therefore, the circuit is broken. This is the way we turn on and off different features of our products using membrane switch.

Why Conductive Ink Is Used?

There are many other conductive materials available as a replacement for the conductive ink. So, why we still use conductive ink instead of other materials in a printed membrane circuit? Among all other materials, ink is a highly preferred option because it requires very little or even no space. A membrane switch is usually very small. Therefore, it needs supportive components to be small also.

Because conductive ink takes no or little space, so it becomes an ideal solution in case of a membrane switch design. Apart from conductive ink, some membrane switches also utilize copper ink. Some designs also include graphite or silver ink to complete the circuit.

Things to Know Before Choosing Your Membrane Switch

Apart from the conductive ink, there are some other points that you should also consider before choosing your membrane switch. For instance, a few membrane switches have features like backlighting. These switches support LEDs (light-emitting-diodes), EL (electroluminescent), and fiber optics backlighting.

Among these three options, the highly preferred option is the LED backlighting. LEDs are more energy-efficient and also more durable to last longer. There are many other benefits of considering a membrane switch over others. We will discuss those benefits in detail in our next articles about membrane switches and their benefits.

Summary

Conductive inks are a mandatory element to complete a printed membrane circuit in any membrane switch design. It is made from different materials, like graphite, copper, carbon, and silver by infusing them. Membrane switches are available in different types and they are compact switches like your TV remote control.

Conductive inks need less or even no space, so they become an ideal choice for the membrane switches. We hope this article clears your concept about the membrane circuits and the role of conductive inks in making them function.

For More Information, Contact Us Today!

![]()