What do you need to Know about Membrane Keypad?

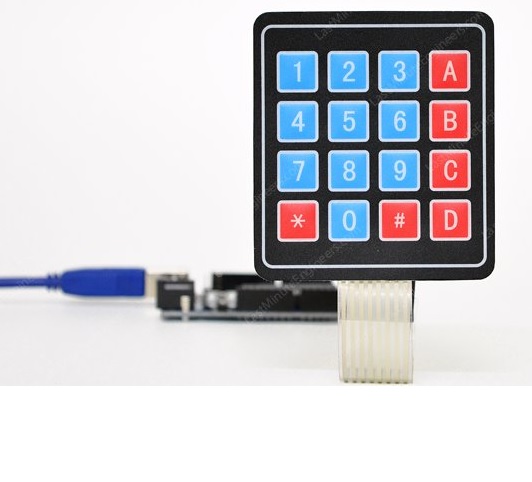

Introduction to Membrane Keypad

Equipment modernization demands professional input systems where human beings and machines interact frequently. A membrane keypad is an interface input system that usually shapes a well-designed and aesthetic user interface between the control system’s hardware and its software. Its appearance marks a fundamental change in the configuration of printed, electronic products. This operating system involves inseparable pressure design pads that integrate symbols and outlines printed on a malleable flat surface. Comprising of an instrument panel, indicator panel, and critical function, this interface is also known as a touch keypad due to its tactile feedback. Manufacturers design it to meet customers’ requirements in terms of design, size, graphics, and other components.

Most manufacturers consider copper-laminated base membranes for such a high-quality keypad because it is incredibly flexible. As a result, the probability of breaks to membrane cable is almost diminished. Instead of applying adhesive, they solder LEDs and other components for better security. As the user presses the keypad buttons, it operates through an electrical connection between its surface and its circuits. The basic standard of functionality is that the key's contact closes an open loop of the circuit, which terminates on the flexible printed circuit.

Tactile feeling is the key element behind the haptic operability of the keypad. The keypad design concentrates on the choice of the design of the key contour and even distribution of pressure on the snap dome. You see their use in domestic and industrial applications on a wide variety ranging from capacitive touch fascia to backlit keypads, imprinted versions, and many more. Many industries, consumer electronic products, security appliances, marine and medical equipment use membrane based keypad.

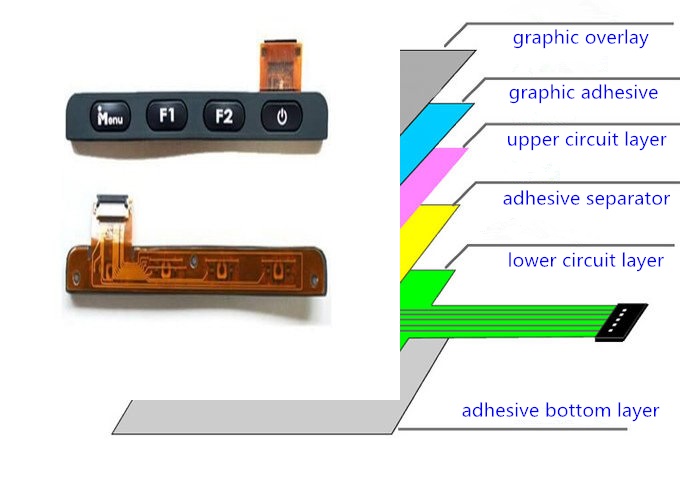

Structure of a Membrane Keypad

The typical membrane based keypad integrates six layers.

Graphic overlay

With embossing eye-catching screen-printed patterns and texts, the graphic overlay undertakes part functional and part aesthetic liability. The customized graphic overlay is highly durable, water and dustproof, and resilient against extreme temperatures.

Graphic adhesive layer

It connects the upper circuit layer with a membrane overlay. The adhesive usually is die-cut to avoid the keys or window area. This structure forms the connection and sealing effect.

Upper circuit layer

You have to place a flexible upper circuit layer under the graphic adhesive layer. Later, you should attach a metal dome to it using a single layer of glue to enact tactile feedback.

When you press a key, the upper circuit layer deforms downward to connect with the lower circuit layer. When pressure is released, a tactile feel is felt as the upper circuit contact bounces back to trigger a signal.

Adhesive separator

Beneath the upper circuit is an adhesive separator with customized thickness to form sealing and connection.

Lower circuit layer

A lower flexible printed circuit layer lies under the adhesive separator, which usually uses a polyester film to form a viable switching circuit pattern. The electrical conductivity is formed through conductive silver plates and conductive inks. The thickness of a flexible printed circuit can bear air tightness, heat resistance, and flexural resistance, thereby forming an ideal keypad base. In some cases, you have to connect the lower circuit to machine interfaces through terminals.

Rear adhesive layer

You attach a rear adhesive layer below the lower circuit layer with double side tape.

Characteristics

The characteristics of the membrane based keypad take into account

- electrical performance, which takes care of voltage, consumption of electric current, insulation resistance, bouncing time of contact, and contact element, such as snap dome

- mechanical properties, which look after the geometrical aspects including size, embossing, the height of the key, actuation force, operating temperature, substrate, and resistance against chemicals

- environmental performance

Types

There are three types of membrane based keypad: a) flexible membrane based keypad, b) rigid membrane based keypad, and c) raised membrane based keypad

Manufacturing Process of a typical Membrane Based Keypad

The categorical manufacturing process involves:

- Heat shaping polyester substrate

- Screen printing

- Baking

- The positioning of holes

- ICT test to check the conductivity and insulation of flexible lower printed circuit followed by visual inspection of circuits

- After that, you need to laminate the graphic adhesive, upper circuit layer, and adhesive separator by hand to avoid deviation before installing metal domes for tactile impact.

- The whole process performed until this stage forms a semi-finished membrane based keypad, which is then die cut as per requirement.

- All the layers are assembled and laminated by the machine under hard pressure before an FT test is conducted to test the open circuit, short circuit, insulation, and conductivity. Finally, the finished product’s appearance is scrutinized to remove scratches, dirt, any deviation, etc., before conducting the spot-checking to ensure that product is functioning correctly.

Advantages of Membrane Keypad

Flexible and Versatile

Due to its captivating, crisp design and features, various industries leverage it in different applications, ranging from handheld gadgets to physical exercising equipment. Due to its flexibility, it is highly adaptable to any application.

Durable

Manufacturers generally use two types of substrates for creating the membrane. A) Polycarbonate, also called Lexan, and b) Polyester. These substrates are durable, but their choice varies according to the functional requirement of the keypad. Polyester is a little expensive; however, a polyester membrane-based keypad offer benefits like stability against heat, embossing raised keys, and laser cutting.

Polycarbonate substrate increases the product's aesthetic look through die-cutting, ink keying, dye cutting, forming, etc.

Moisture, Liquid, and Dust Resistant

The adaptive design of the membrane keypad is based on a single layer so that the keys are not separate from one another. As a result, the fully sealed membrane’s surface remains safe from dust, water, moisture, and chemical ingress.

As long as the membrane surface remains intact, the circuity that controls the keypad remains protected from external environmental impacts and damages and functions smoothly. Similarly, the keypad can survive the harsh UV lights when exposed to the external environment.

Stable and Reliable

The membrane based keypad relishes high stability and reliability due to its magnificent design and structure. It can bear thousands of strokes before needing replacement.

Cost-effective and Easy to Maintain

The material used in the keypad’s membrane is exceptionally durable. And since the keypad itself is dust and moisture-proof and more comfortable to clean, it becomes an inexpensive unit and does not require frequent maintenance or replacement. If damage occurs to the circuitry, you will have to remove the membrane overlay to repair the circuit and make the keypad fully operative.

Tactile Feedback

The dome switches fused in the membrane critically provide a noticeable, crisp, and tactile response.

Compact Design

The low profile keypad features a compact design allowing it to fit in applications that do not need much space.

Backlighting Lighting Impact

Sometimes, the operations are carried under dark situations. Thus, the keypad incorporates the homogenous distribution of light using inexpensive backlighting components, such as LEDs, for high visibility of symbols, texts, and graphics under specific situations demanding dark surroundings. The LED placed in the middle of the key field on the back of the printed circuit board distributes the light evenly.

Conductive Traces

The conductive traces inducted at the bottom of each key turn the keypad into an electrical switch. The key switches are in an open circuit initially. When a user presses a key, the action bridges the gap in the conductive traces to close the circuit.

Summary

The fantastic graphic overlay, workable circuit, embossing with impressive-feeling, water, dust, heat resistance, shielding, and accessories like LEDs are typical features of a membrane keypad. In addition, the tactility, durability, and exceptional stability of the product against harsh environments make it an unparalleled customized product.

In order to learn more about membrane switches, Contact Us Today!